effective inventory control

Inventory control and stock management are essential aspects of any business that deals with physical products. The process involves tracking and managing the flow of goods to ensure optimal levels of stock while minimizing waste and losses. With the advent of digital technologies, traditional inventory control and stock management methods are rapidly becoming obsolete. This article explores the current state of inventory control and stock management, the challenges businesses face, and how modern technology can help overcome these challenges.

The Traditional Approach to Inventory Control and Stock Management

In the past, inventory control and stock management were primarily done manually. This involved keeping track of the stock on hand, recording sales and purchases, and forecasting future demand. However, this approach was time-consuming, error-prone, and often led to stock shortages or overstocking. The traditional approach relied heavily on human intervention and was prone to human error. Inventory control was done through manual counts and audits, and stock management was based on estimates and forecasts. This often led to inaccuracies in inventory levels, which resulted in stockouts or overstocking. In addition, manual data entry was tedious and time-consuming, leading to inefficiencies in the entire process.The Challenges of Modern Inventory Control and Stock Management

Today, businesses face new challenges in inventory control and stock management. The rise of e-commerce has created new sales channels, leading to increased demand and more complex supply chains. The globalization of markets has also made it challenging to manage inventory across multiple locations and time zones. Additionally, businesses must deal with the threat of theft, spoilage, and damage to their products. One of the biggest challenges businesses face in inventory control and stock management is the increasing complexity of the supply chain. With the rise of e-commerce and omnichannel retail, businesses must manage inventory across multiple sales channels. This can make it difficult to track inventory levels, forecast demand, and optimize stock levels. Additionally, managing inventory across multiple locations and time zones can be a logistical nightmare. Another challenge is the increasing threat of theft, spoilage, and damage to products. In today’s fast-paced business environment, businesses must move products quickly to meet customer demand. This can increase the risk of theft, spoilage, and damage to products, especially during transportation and storage.The Benefits of Digital Technologies in Inventory Control and Stock Management

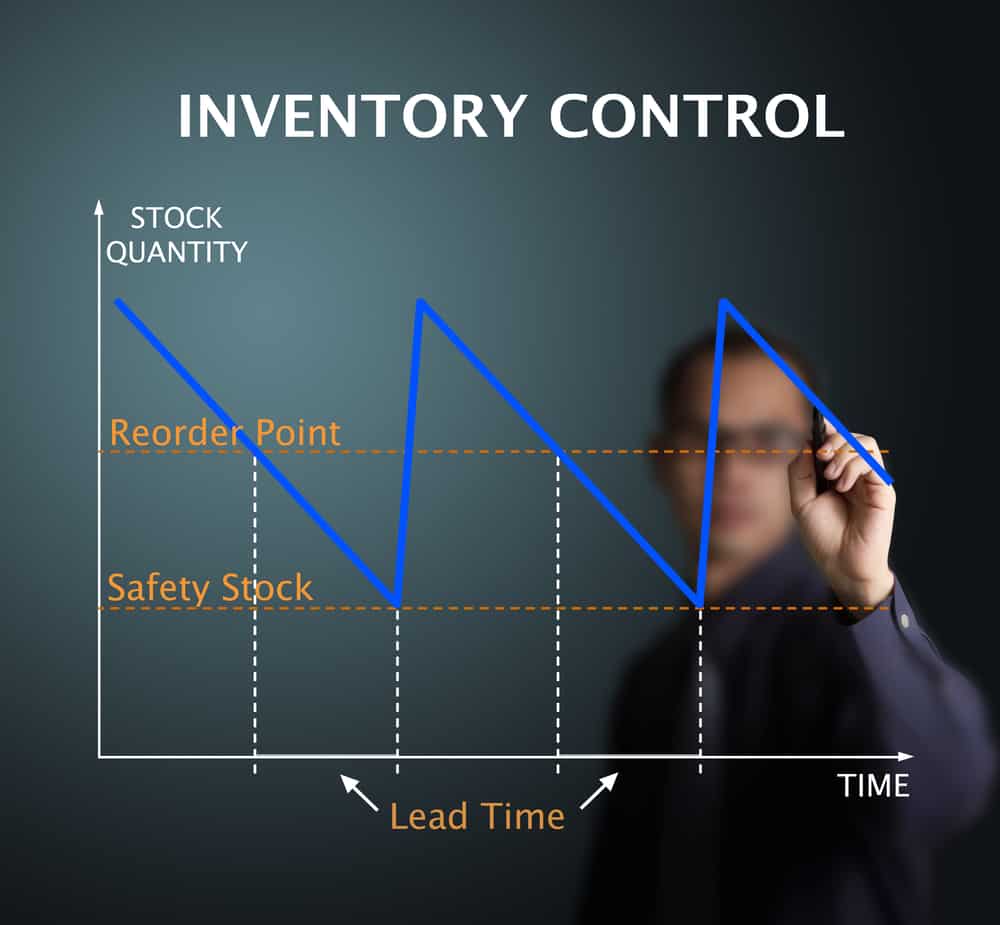

Fortunately, modern digital technologies have revolutionized inventory control and stock management. Using advanced software and analytics, businesses can now track their inventory in real-time, forecast demand accurately, and optimize stock levels. For example, Radio Frequency Identification (RFID) technology can be used to track inventory in real-time, reducing the need for manual inventory checks. Similarly, automated inventory management systems can automatically reorder stock when it reaches a certain level, ensuring that businesses always have the right amount of stock on hand. There are many benefits of digital technologies in inventory control and stock management. One of the biggest advantages is the ability to track inventory in real-time. This allows businesses to have accurate, up-to-date information on inventory levels, making it easier to manage inventory across multiple locations and sales channels. Additionally, digital technologies can help businesses forecast demand more accurately, reducing the risk of stockouts or overstocking. Finally, automation can help businesses save time and money by reducing the need for manual data entry and inventory checks.Examples of Digital Technologies in Inventory Control and Stock Management

There are several digital technologies that businesses can use to improve inventory control and stock management. These include:- RFID Technology: RFID tags can be used to track inventory in real-time, reducing the need for manual inventory checks. RFID technology can be used to track products at every stage of the supply chain, from the warehouse to the store shelf.

- Barcode Scanning: Barcode scanning is another popular technology used in inventory control and stock management. Barcodes can be scanned using a handheld device, allowing businesses to track inventory levels in real-time. Barcode scanning is particularly useful for businesses that operate across multiple locations or sales channels.

- Automated Inventory Management Systems: Automated inventory management systems use advanced software to manage inventory levels automatically. These systems can automatically reorder stock when it reaches a certain level, ensuring that businesses always have the right amount of stock on hand. Automated inventory management systems are particularly useful for businesses with high-volume inventory and multiple sales channels.

- Cloud-Based Inventory Management Software: Cloud-based inventory management software is a powerful tool that allows businesses to manage their inventory from anywhere, at any time. These systems use advanced analytics to track inventory levels, forecast demand, and optimize stock levels. Cloud-based inventory management software is particularly useful for businesses with complex supply chains and multiple sales channels.

Best Practices for Effective Inventory Control and Stock Management

While digital technologies can help businesses improve their inventory control and stock management, there are still several best practices that businesses should follow to ensure optimal results. These include:- Regular Inventory Audits: Regular inventory audits are essential for ensuring accurate inventory levels. Businesses should conduct regular audits to identify any discrepancies in inventory levels and address them promptly.

- Accurate Demand Forecasting: Accurate demand forecasting is essential for optimizing stock levels and avoiding stockouts or overstocking. Businesses should use advanced analytics to forecast demand accurately and adjust stock levels accordingly.

- Efficient Supply Chain Management: Efficient supply chain management is critical for ensuring the timely delivery of products and minimizing waste and losses. Businesses should work closely with their suppliers and logistics providers to optimize the supply chain and reduce lead times.

- Employee Training and Engagement: Employee training and engagement are essential for ensuring effective inventory control and stock management. Businesses should provide their employees with the necessary training and support to ensure that they can use digital technologies effectively and efficiently.