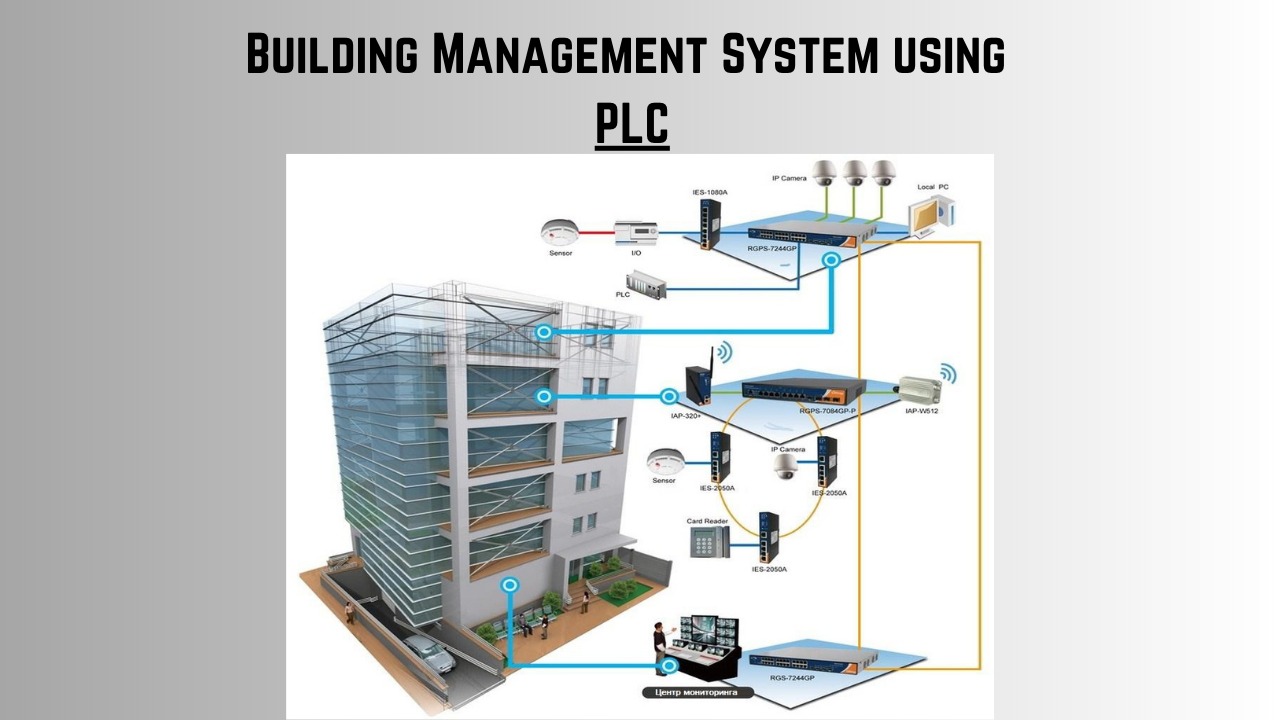

PLCs, also known as programmable logic controllers, are now a crucial part of contemporary building automation systems and energy management solutions. They offer a quick, adaptable, and affordable method for managing and controlling numerous systems.

An industrial or building management is a multi-faceted business that requires a significant amount of personnel and material resources to run. In order to achieve the combined goals of high production and employee satisfaction, safety and maintenance should be one of any profit-driven industry’s top priorities.

Thus, a plant’s security is crucial in preventing mishaps that might result in significant financial and human losses. Industries have been safe for a very long time. With the development of Allen Bradley PLC technology, specialized software for safety and control applications was first used. With the introduction of modern technologies, circumstances have drastically changed, making it necessary to watch the live process in a system from a control room.

The ability to supervise, regulate, and contain the entire process to a small control room has been made feasible by the advent of SCADA (Supervisory Control and Data Acquisition).

A software package called SCADA includes features including alarm popups, history files, graphical representations, animations, and more. Internal light control, external light control, water level management, and fire detection are the main factors being watched.

Following are some specific applications for PLCs in building automation and energy management systems: